Temperature control and stability are essential to ensure various activities such as the operation of technology or the safety of the products we consume.

The “cold chain” is indispensable in all stages of food logistics: processing, transportation, storage, and cooking.

However, it is also crucial for various equipment and processes in the medical, industrial, and data server fields.

In this article, we will explore the importance of implementing an effective temperature control system, its benefits, and how it works.

What is a temperature control system?

A control system is used to monitor and/or correct the thermal state of processes in which temperature is a crucial factor to guarantee quality.

Temperature control is a fundamental part of technology in numerous applications, increasingly so.

Additionally, it is important to consider the responsibilities related to temperature recording and calibration of measuring equipment that we must comply with according to regulations in our industry.

Why is temperature control important?

Firstly, it is essential to understand why temperature control is vital in environments such as server rooms, refrigeration chambers, and cold storage warehouses.

The computer equipment housed in a data center or server room generates a significant amount of heat, which is why computers and other electronic devices are equipped with cooling systems such as fans or heat sinks to help regulate the temperature.

However, in a facility with a high concentration of equipment, such as a data center, this is not enough. According to various experts, the allowed temperature range for a server room typically fluctuates between 59°F and 80,6°F. The optimal range is between 69,8ºF and 73,4ºF. As for relative humidity, a range of 20% to 80% is permitted.

Servers are constantly running, and the data stored in them continues to grow, increasing the operations performed by the equipment and raising their temperature.

If the temperature exceeds a certain threshold, the heat can cause equipment downtime or damage internal components, potentially leading to the loss of valuable information.

If the temperature is too low, the cooling costs can become excessively high. Inefficient cooling can result in costs that are twice as high as the cost of the servers themselves. Moreover, it can have a significant environmental impact. Maintaining an optimal and properly regulated temperature minimizes the environmental impact and promotes environmentally sustainable practices.

Therefore, the goal is to maintain the facility at the highest temperature possible that ensures the proper functioning of servers and the protection of stored data.

What about the food industry?

As mentioned earlier, temperature control is essential in all stages of food handling to ensure food safety. Proper temperature control becomes crucial in preserving the freshness of food, preventing the proliferation of pathogenic bacteria, and ensuring maximum quality at every step of the process.

Any fluctuations in temperature can accelerate product degradation, pose health issues, or result in financial losses.

The appropriate tempeature must be maintained not only in factory refrigerators or freezing chambers but also during transportation and wholesale or retail trade.

It is important to consider that different regulations for temperature control exist depending on the specific food-related business. However, a common requirement is the need to maintain a daily temperature record that is documented and available to health authorities.

In all these cases, temperature control is achieved through the use of temperature sensors, alarms that notify about thresholds and fluctuations or malfunctions, regulation systems (such as thermostats), and cooling or heating devices as necessary. Automated control technology, such as temperature controllers and feedback control systems, is widely used to maintain the desired temperature precisely and efficiently.

At SEGURIDADE A1, we offer the latest technology in TEMPERATURE CONTROL SYSTEMS.

This solution is specially designed for refrigeration chambers, freezing units, cold storage warehouses, server rooms, and computer systems.

But how does our TEMPERATURE CONTROL SOLUTION work?

This technology involves temperature measurement using probes that operate within extreme temperature ranges, from -4°F to 122°F. This allows us to protect temperature-sensitive products, both in refrigerated areas and outdoor environments.

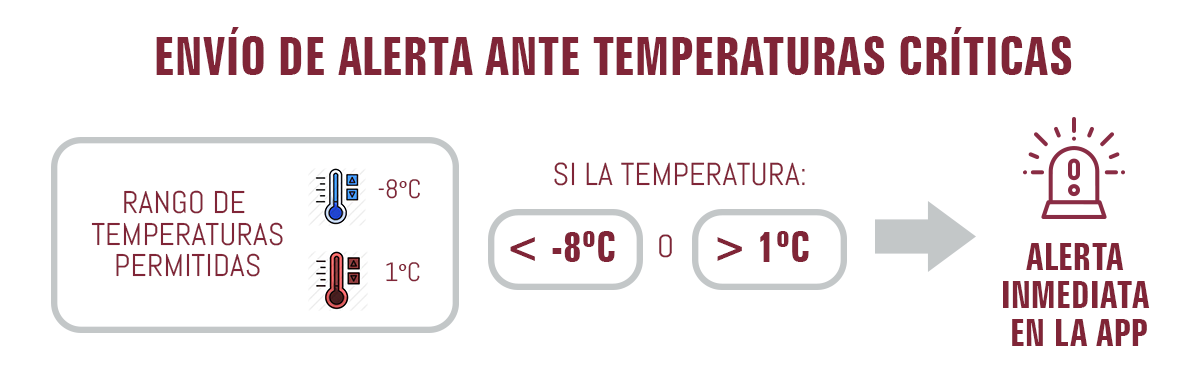

Knowing the acceptable temperature range for proper product preservation, we configure the system with Minimum and Maximum allowed temperatures. If the temperature falls outside this range, the system sends an ALARM.

The system is equipped with a Web Platform and App, through which we have real-time access to temperature reports. We can also record and store these temperatures and the events generated by alarms in the system’s history.

Advantages of the solution:

- Easy installation and setup in less than 8 minutes.

- No wiring required.

- High precision (+/-0,55°F) and reliability of temperature sensors and probes.

- Immediate alarm notifications through the app.

- Operating temperature range: -4°F to 122°F.

An efficient temperature control system is essential for handling contingencies and ensuring an optimal environment in terms of performance, energy efficiency, and safety.

Benefits of an Advanced Temperature Control System:

- Preservation of equipment and product integrity: An advanced temperature control system ensures that the temperature remains within predefined ranges at all times.

- Energy efficiency: A smart temperature control system helps optimize energy consumption by allowing cooling adjustments based on specific needs. This limits energy waste, reduces operating costs, and minimizes environmental impact.

- Real-time alerts and monitoring: Advanced temperature control systems are equipped with sensors and monitoring devices that provide real-time alerts for any deviations from established temperature ranges. This enables quick and efficient intervention to resolve any issues.

- Regulatory compliance: An efficient temperature control system helps ensure compliance with regulations, avoiding legal sanctions and damage to a company’s reputation.

- Integration with other systems: Temperature control systems can be integrated with other management and monitoring systems, such as building automation systems or supply chain management systems. This allows for centralized monitoring and control, facilitating informed decision-making and process optimization.

Whether it’s protecting critical data or preserving valuable products, investing in a reliable and state-of-the-art temperature control system provides long-term benefits in terms of cost savings, operational efficiency, and peace of mind.

If you have any inquiries, feel free to contact us without any obligation. We’ll be delighted to assist you.

If you found this content interesting, you might be interested in: